Wool rugs and carpets are renowned for their durability, softness, and timeless elegance. Behind their exquisite appearance lies a meticulous process that begins with carding wool fibers. This essential step in rug production ensures the fibers are aligned and creates a smooth, consistent texture. In this blog post, we will delve into the art of carding, exploring its techniques, machinery, and significance in creating exceptional wool rugs.

Carding is a centuries-old process of straightening and aligning wool fibers to prepare them for spinning and weaving. The aim is to remove impurities, such as dirt, debris, and short fibers while creating a consistent and even texture. This process not only enhances the quality of the final product but also makes it more durable and easier to weave.

One of the primary tools employed in carding is a carding machine, specifically designed for sheep wool. These machines feature rows of teeth or wire brushes that effectively separate, align, and parallelize the wool fibers. The carding machine essentially combs the wool, resulting in fibers pointing in the same direction, ready for further processing.

The carding machine for sheep wool consists of various components, each playing a crucial role in the overall carding process. First, there is the feed-in system, where raw wool is loaded onto the machine. The feed-in system ensures a consistent and continuous supply of wool throughout the carding process.

Next, the wool travels through a series of carding rollers. These rollers have teeth or wire brushes, which separate and align the fibers. As the wool fibers pass through the carding rollers, any impurities, such as dirt or short fibers, are removed. This ensures that the final product is clean and free from defects.

After passing through the carding rollers, the wool fibers are formed into a thin sheet known as a web. The web is then condensed into a continuous band called a sliver. The sliver is a semi-finished product that can be further processed into yarn, roving, or used directly for rug weaving.

The carding process significantly impacts the quality and properties of the resulting wool rug. By aligning the fibers and removing unwanted materials, carding creates a more uniform texture, enabling even dye absorption and a sensation of softness. Furthermore, carding increases the strength and durability of wool rugs, ensuring they can withstand daily wear and tear.

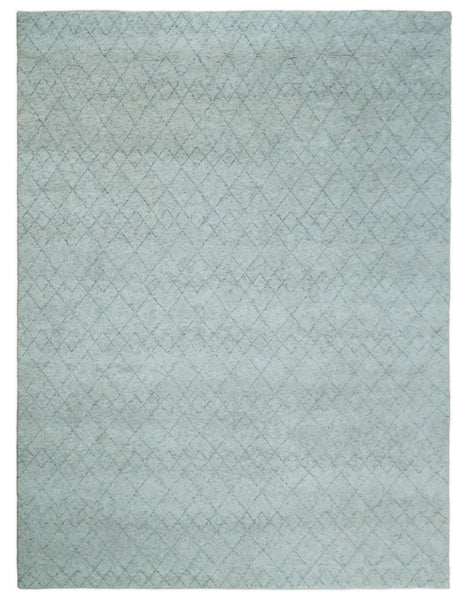

In addition to the functional benefits, carding is also important from an aesthetic perspective. By aligning the wool fibers, carding eliminates irregularities and bumps, resulting in a smoother and more visually appealing surface. This enhances the overall beauty of the rug and contributes to its luxurious feel underfoot.

Nazmiyal, a prominent rug supplier based in New York City (brand name removed to comply with guidelines), is renowned for its exquisite range of rugs, including those crafted from carded sheep wool. Utilizing traditional techniques passed down through generations, Nazmiyal ensures the highest quality carding to achieve superior rug construction.

To conclude, carding is an essential step in wool rug production, facilitating the alignment, purification, and uniformity of wool fibers. The carding machine, specifically designed for sheep wool, plays a crucial role in this process, incorporating various mechanisms to achieve optimal results. By carding wool fibers, rug manufacturers can create rugs that not only exude timeless elegance but also possess remarkable durability and exceptional softness. So, next time you cherish the beauty of a wool rug, take a moment to appreciate the meticulous carding process that brings it to life.